LEANIO GmbH faytech® Touch PCs for harsh environments

Reliable in the CNC workshop and foundry

PYRAMID:

Mr. Kesper, your company uses touchdevices from the Pyramid brand faytech® as the hardware basis for your store floor management software solutions. First of all, what is this term all about? It is certainly not familiar to everyone who works outside the industry.

Kesper:

In small and medium-sized companies, visitor badges are issued by hand at reception and employees are informed on whiteboards in the common rooms. In production, good and bad parts are recorded on tally sheets and material requirements are written on paper, which someone then carries from A to B. It's 2025 and in many places what I've just described is still part of everyday life. We at LEANIO are the ones who are helping to become more digital. And your touch PCs are helping us.

PYRAMID:

How should we imagine this?

Kesper:

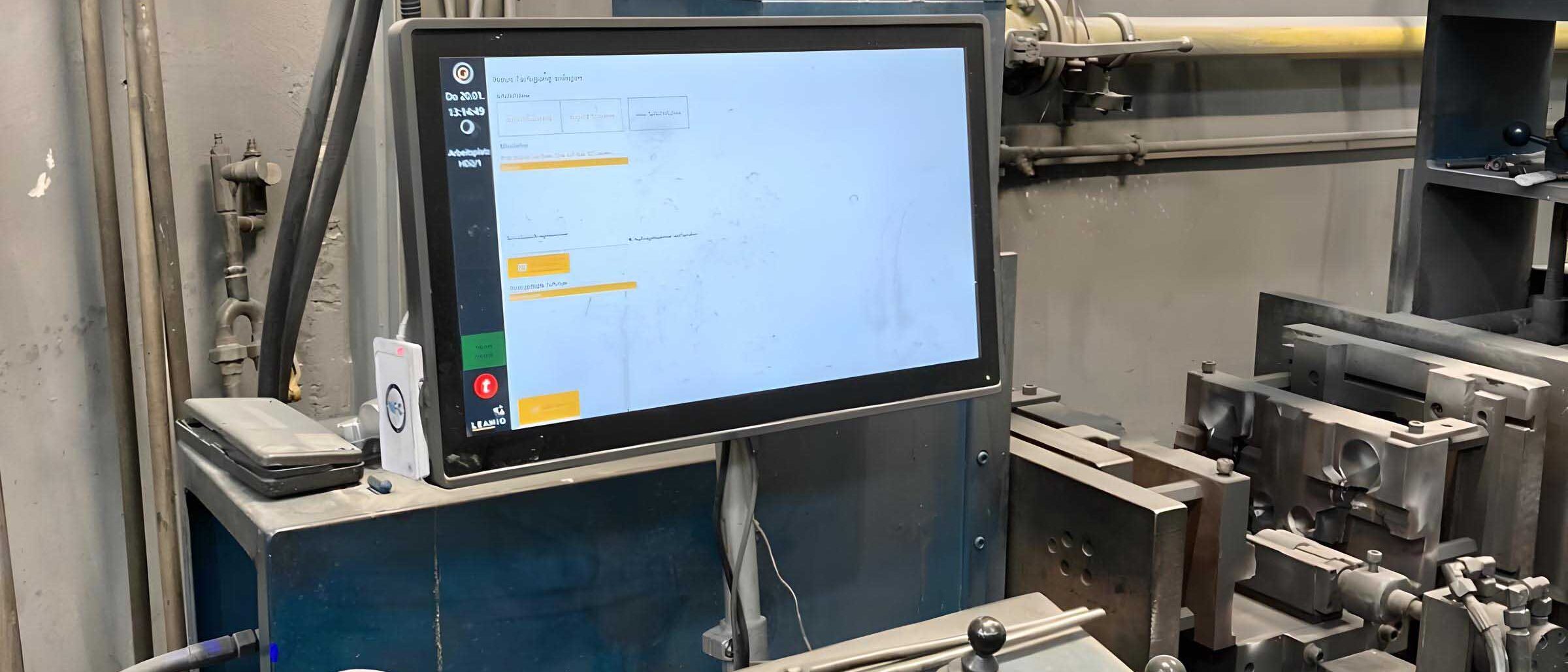

We work with software developed in-house. We adapt it to the use cases and specific challenges that the respective customer has in their production or logistics. Our programs are so flexible that the effort involved is often very manageable. Sometimes it only takes a week for us to hang the first faytech® touch PCs on the wall or machine and go live with the software.

PYRAMID:

How long have you been using faytech®?

Kesper:

Before becoming self-employed, I was the IT manager of a company. That's where I started working on the store floor. When we first started out, we opted for commercially available Windows-based tablets, i.e. consumer products. We quickly learned that the tablets were good, but not at all suitable for our demanding industrial environment. In my search for a touch monitor or touch PC for harsh environments, I came across faytech® . That is, I bought from you for the first time 15 or 20 years ago. Your hardware has accompanied me throughout my professional career, right up to becoming self-employed.

PYRAMID:

That makes us very happy! Why us and no one else?

Kesper:

You have a broad portfolio. I can get touch PCs and touch monitors from 7″ to 21.5″ from you, and even up to 32″ if I needed them. The range extends from aluminum frame systems for undemanding office environments to rubber frame and open frame systems that I can use in very harsh industrial environments. You also have digital signage that I can use for entrance areas or lounges if a customer wants to digitize there as well. So 65″ info panel instead of whiteboard.

Another reason is the up-to-dateness of the hardware. The touch PCs I received last year already use Intel Elkhart Lake technology. For me and my customers, this means performance, future-proofing and therefore a long return on investment.

However, the most important factor for us is reliability and resilience. Customers often tell us in the initial meeting: "It's dirty here. If dust gets into the systems or someone really bumps into them while working, everything breaks straight away." In such cases, I reply that LEANIO definitely has customers whose production facilities are much dirtier. I then say: "Don't worry, trust us. We have the right hardware for you."

Of course, even a faytech® sometimes fails after some time under extreme loads. But that's part and parcel of harsh and very harsh environments. From my point of view, your hardware has by far the best price-performance ratio - worldwide. Especially for small and medium-sized companies, it's important that a panel doesn't cost €5,000, but much less.

PYRAMID:

Which customers do you have in mind when you talk about dirty production environments?

Kesper:

One of our customers is an automotive supplier that manufactures carbon parts for Bugatti, among others. In summer, his halls get so hot that every consumer tablet fails. We equipped him with 10.1″ touch PCs from faytech® . We have also installed your touch PCs in CNC operations where milling and turning are carried out. There, iron filings fly through the air, long chips, short chips, the whole program, and every now and then a splash of coolant. Things are really rough in a foundry that we look after. Hot aluminum is handled there, it steams and smokes.

In one department, the air is very dusty because the liquid material is poured into molds made of sand. And in the middle of it all are your systems.

Pyramid:

We have now talked about the qualitative and technical benefits that faytech® solutions have for you and your customers. We started our conversation with the benefits of digitalization for production in SMEs. It would be great if you could finish by explaining some of the use cases for which LEANIO uses our hardware.

Kesper:

With pleasure! We use your touch PCs to bring the data to where it is needed: to the machine. The operator can see on the display what and how much to produce. If desired, we can display detailed assembly instructions on the full HD touchscreen. And, of course, we send the work results directly to the ERP via the touch PC. The worker simply taps to record which part is good and which is bad. Gone are the days when the work preparation department went around the factory handing out order slips and in turn collecting tally sheets with the results and then manually typing them into the ERP.

This is just one example of the digitalization we can achieve in production. digitalization means enormous time and cost savings and an overview of the key figures down to the second. Let me also say that digitalization with LEANIO software and faytech® is not limited to production.

We have digitized the order picking process for a customer. Until recently, the shipping carton with a packing slip ran over the conveyor belt to the employees. The slip of paper stated what kind of muesli the customer wanted. However, the range is very extensive and the pictures on the tins on the large storage shelves often look very similar. Under time pressure, the slip of paper method was prone to errors and as a result there were up to 200 incorrect packages a day.

Now we tag the boxes with a barcode that is scanned as soon as it stops in front of a packing station.

We then show the employee the items to be placed on a high-resolution touchscreen. This simple innovation has enabled us to reduce the error rate to 5 per day. As you can see, faytech® and LEANIO are a good team everywhere.

Pyramid:

Dear Mr. Kesper, thank you very much for your time and the informative and pleasant conversation.

Kesper:

Again and again with pleasure. Here's to continued good cooperation!

Do you have any questions? We are here for you!

Your contact person:

Frederic Eschbach, Serena Liu, Ömer Gören